Improving the Performance of Activated Sludge Systems — An Operator’s Perspective

It is generally accepted that aerobic biological treatment systems are robust and stable to the extent that eight key growth pressures are controlled:

- Organic...

Posts about:

It is generally accepted that aerobic biological treatment systems are robust and stable to the extent that eight key growth pressures are controlled:

EBS believes that monitoring the microbiology (biomass) of your activated sludge system or aerated stabilization basin (ASB) is just as critical as any other test...

A common problem in aerated stabilization basins (ASBs) is oxygen deficiency. This can arise for a variety of reasons, such as a power outage, aerators being...

Bacteria are present throughout an aerated stabilization basin (ASB), though their form and concentration may differ in the different areas of the ASB. At the front end of the ASB, where the influent enters and there is the highest concentration of biochemical oxygen demand (BOD), bacterial concentrations are higher and bacteria are dispersed as they are busy consuming the BOD. At the back end of the system, where BOD is sparse, bacteria form floc and settle out. The bacterial growth curve, as seen in Figure 1, characterizes the different growth stages of bacteria in relation to the amount of food (BOD) available.

bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbFigure 1: The Bacterial Growth Curve

bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbFigure 1: The Bacterial Growth Curve

The growth rate of the bacteria in the ASB is directly proportional to the amount of BOD available. Figure 1 shows the growth rate of the bacteria over time. The blue curve represents the amount of BOD available for consumption. The red curve represents the amount of bacterial mass in the bulk water. There are four distinct phases of bacterial growth: lag phase, log phase, declining growth phase and endogenous respiration phase.

Primary clarification is the physical treatment process of removing solids before biological treatment. It is the most cost effective way to remove these solids after basic screening. Process water enters the clarifier tank and floatable solids (scum) are removed from the surface by skimmers while settleable solids (sludge) are collected on the bottom by a rake and removed via a sludge removal system. Effluent destined for biological treatment leaves the clarifier over a weir. The expected range for percent removal in a primary clarifier is 90%-95% settleable solids, 40%-60% suspended solids, and 25%-50% total BOD5.

Clarifier efficiency is based on hydraulic detention time, temperature of the water, the design of the tank and the condition of the equipment. Poor clarifier performance can be due to a variety of factors such as (1) hydraulic overload which decreases hydraulic detention time; (2) hydraulic under-load which doesn’t allow the equipment to work efficiently; (3) sludge buildup which causes decreased tank volume; and (4) highly concentrated waste streams. Bypassing a clarifier, which means routing plant effluent directly to secondary treatment in an aeration basin, should be done only in emergencies when clarifier equipment must be repaired or the sludge removal system is not able to process the sludge volume it receives. This scenario introduces high solids and elevated BOD levels into the biological treatment system and is not advised.

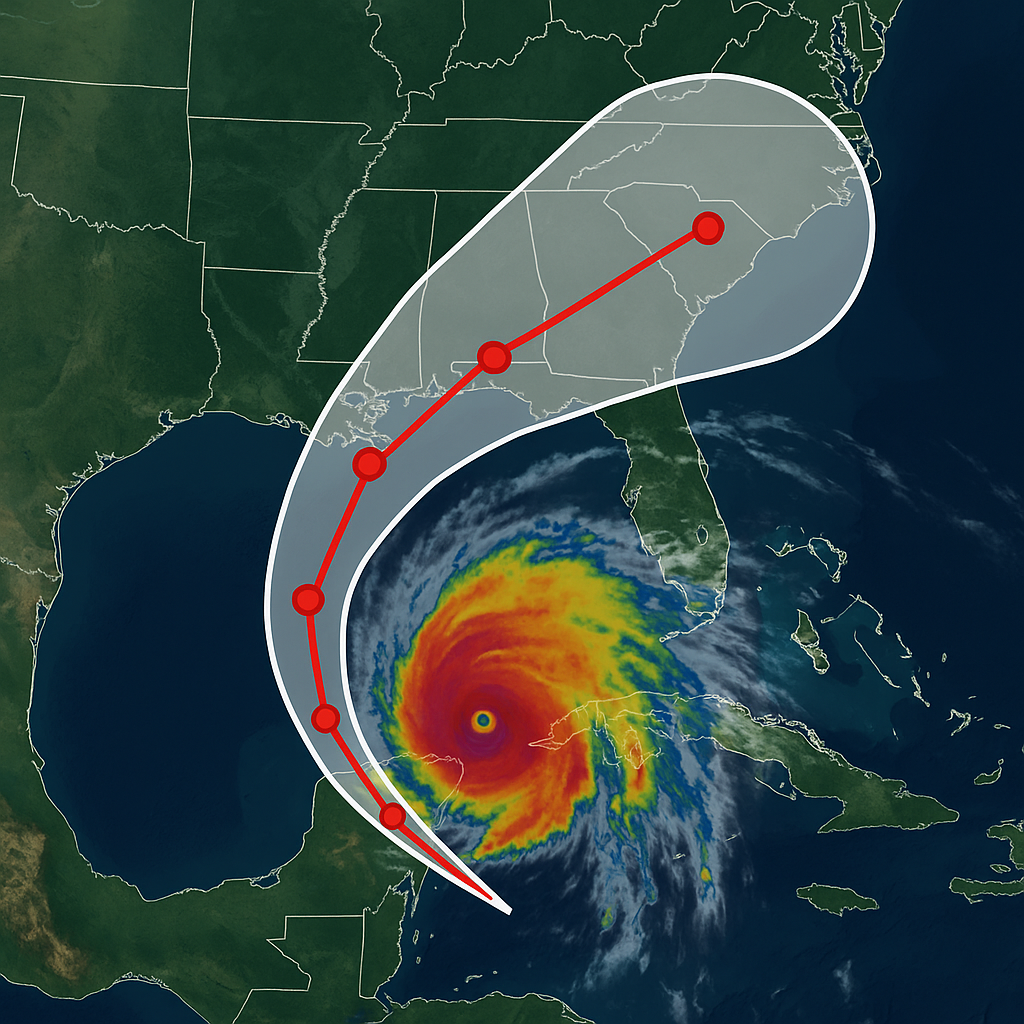

Severe storms and hurricanes can cause widespread devastation—damaging infrastructure, displacing employees, and disrupting operations. For industrial facilities...

In the Kraft paper-making process white liquor, which is NaOH (sodium hydroxide) and Na2S (sodium sulfide), is used to “cook” wood chips in a piece of equipment...

TSS testing measures the total concentration of suspended (non-soluble) solids in the aeration stabilization basin (ASB) or in effluents. The total suspended solids (TSS) data is critical in determining the operational behavior of a waste treatment system. It is usually a permitted test and solids must be kept at a minimum.

In order to test the total suspended solids, a well-mixed sample should be filtered through a weighed standard glass-fiber filter. The residue left on the filter is dried to a constant weight at a temperature between 103 °C and 105 °C. The increase in the weight of the filter represents the total suspended solids of the sample. Large floating particles or submerged agglomerates of nonhomogeneous materials from the sample may be excluded in the total suspended solids measurements if it is determined that their inclusion is not representative of the entire sample. The size of sampling should also be limited to a size that yields no more than 200 mg residue.

MLSS testing measures the total concentration of mixed liquor suspended (non-soluble) solids in the aeration basin of an activated sludge system. The mixed liquor...